Sida loo hagaajiyo cabbiraadaha hannaanka loo shubay ee qiyaasta spheroidization-ka

Heerka spheroidization-ka ee caadiga ah ee loo yaqaan 'spheroidal graphite castray cast cast iron' ayaa looga baahan yahay inuu gaaro heerka 4 ama ka sareeya, (taasi waa, heerka qanjirka 'spheroidization rate' waa 70%), qiyaasta spheroidization ee lagu gaaro aasaaska guud waa qiyaastii 85%. Sanadihii la soo dhaafay, iyada oo la horumarinayo wax soo saarka birta ee loo yaqaan 'nodular cast iron steel', gaar ahaan warshadaha leh shuruudaha sare ee soosaarida tamarta dabaysha iyo tayada tuubista, heerka qanjirka 'spheroidization' ayaa looga baahan yahay inuu gaaro heerka 2, taas oo ah, xaddiga spheroidization wuxuu gaarayaa in ka badan 90%. Shirkadda qoruhu waxay falanqeeyeen oo ay hagaajiyeen hannaanka spheroidization-ka iyo tallaalka ee loo adeegsaday QT400-15, iyo sidoo kale wakiilka daawada spheroidizing iyo inoculant, sidaa darteed heerka qanjirka 'spheroidization of iron cast cast nodular wuxuu gaadhay in ka badan 90%.

1. Habka wax soo saarka asalka ah

Nidaamka wax soo saarka asalka ah:

- Qalabka dhalaalaya wuxuu qaataa 2.0T foornada hirarka dhexdhexaadka ah iyo 1.5T foornada soosaarka warshadaha;

- Waxyaabaha ay ka kooban tahay QT400-15 dareeraha birta ceyriin waa ω (C) = 3.75% ~ 3.95%, ω (Si) = 1.4% ~ 1.7%, ω (Mn) ≤0.40%, ω (P) -0.07%, ω ( S)) -0.035%;

- Daawada spheroidizing loo isticmaalo daaweynta spheroidizing waa 1.3% ilaa 1.5% RE3Mg8SiFe alloy;

- Cirbadaha sunta ah ee loo isticmaalo daaweynta cirbadeynta waa 0.7% ~ 0.9% 75SiFe-C alloy. Daaweynta spheroidizing waxay qaadataa laba hab oo taabasho iyo biyo nadiifin ah:

Marka hore, 55% ~ 60% birta ayaa la soo saaraa, ka dibna spheroidizing ayaa la sameeyaa, ka dibna sunta ayaa lagu daraa, ka dibna inta kale ee dareeraha birta ah ayaa lagu daraa.

Sababtoo ah habka dhaqameed ee loo yaqaan 'spheroidization and inoculation', qiyaasta spheroidization-ka ee lagu ogaado hal baako oo tijaabo ah oo dhumucdiisuna tahay 25 mm guud ahaan waa kudhowaad 80%, taas oo ah, heerka spheroidization waa 3.

2. Qorshaha tijaabada si loo hagaajiyo heerka spheroidization

Si loo kordhiyo xaddiga spheroidization-ka, hannaanka asbaaska iyo tallaalka asalka ah ayaa la hagaajiyay. Tallaabooyinka ugu muhiimsan waa: kordhinta xaddiga wakiilka spheroidizing iyo sunta jirka lagu nadiifiyo, nadiifinta birta la dhalaalay, iyo daweynta daweynta. Qiyaasta spheroidization-ka waxaa wali lagu tijaabiyaa hal tijaabo oo cabiran oo 25 mm ah. Qorshaha gaarka ahi waa sida soo socota:

- (1) Falanqee sababta sababta heerka spheroidization-ka hooseeya ee habka asalka ah. Waxaa loo maleynayay in xaddiga wakiilka spheroidizing uu yar yahay, sidaa darteed qadarka loo yaqaan "spheroidizing agent" ee lagu daray wuxuu ka kordhay 1.3% ilaa 1.4% ilaa 1.7%, laakiin heerka spheroidizing ma uusan buuxin shuruudaha. . (2) Qiyaas kale ayaa ah in xaddiga spheroidization-ka hooseeya ay sababi karto uur xumo ama taranka oo hoos u dhaca. Sidaa darteed, tijaabadu waxay kordhisay qiyaasta tallaalka min 0.7% ilaa 0.9% ilaa 1.1%, iyo heerka spheroidization-ka ma uusan buuxinin shuruudaha.

- (3) Sii wad inaad falanqeyso oo aad rumeysato inay jiraan waxyaabo badan oo ka mid ah birta la shubay iyo walxaha faragelinta sare ee spheroidization ayaa laga yaabaa inay sabab u tahay heerka hoose ee spheroidization. Sidaa darteed, nadiifinta heerkulka sare ee birta dhalaashay ayaa la sameeyaa. Heerkulka isdaahirinta ee heerkulka sare waxaa guud ahaan lagu xakameeyaa 1500 ± 10 ° C, laakiin heerka qanjirka 'spheroidization' kama uusan dhaafin 90%.

- (4) Qadarka sare ee ω (S) wuxuu si dhab ah u cunaa qiyaasta spheroidizing wuxuuna dedejiyaa hoos u dhaca spheroidization. Sidaa darteed, daaweynta sunta baab'inta ayaa la kordhiyay si loo yareeyo asalka asalka ah ee dareeraha ω (S) laga bilaabo 0.035% in ka yar 0.020%, laakiin heerka qanjirka 'spheroidization' ayaa sidoo kale Kaliya la gaarey 86%. Natiijooyinka imtixaanka ee afarta qorshe ee kor ku xusan waxaa lagu muujiyey Shaxda 1. Qaab-dhismeedka iyo astaamaha farsamo ee baaritaanka buundada qaab-qaabeedka ah ma aysan buuxin shuruudaha.

3. Qorshihii hagaajinta ee ugu dambeeyay ee la qaatay

3.1 Qiyaasaha hagaajinta gaarka ah

- Qalabka ceyriinka waa birta doofaarka, xoqan ama qashin yar oo daxal ah iyo qalabka kululeynta;

- Baabi'inta birta la dhalaalay ee ceyriin iyadoo foornada lagu daro ash ash (Na2CO3);

- U adeegso wakiilka daaweynta ee Foseco 390 si aad pre-deoxidize ugu sameysid boorsada;

- Daaweynta xinjirowga ee Fozco Nodulizer;

- Isticmaalka carbide silicon iyo ferrosilicon tallaalka isku dhafan.

Xakamaynta macdanta birta asalka ah ee nidaamka cusub: ω (C) = (3.70% ~ 3.90%, ω (Si) = 0.80% ~ 1.20% [casting ω (Si final) = 2.60% ~ 3.00%], ω ( Mn) ≤ 0.30%, ω (P) -0.05%, ω (S) ≤0.02% .Marka birta dhalaalaysa ee asalka ah ω (S) ay dhaafto 0.02%, dambaska soodhaha warshadaha waxaa loo isticmaalaa in lagu baabi'iyo foornada horteeda, maxaa yeelay falcelinta baabba'a waa falcelin kuleyl daran, Heerkulka baab'inta waxaa loo baahan yahay in la xakameeyo qiyaastii 1500 ° C, iyo qadarka soodhada lagu daro ee lagu daro waxaa lagu xakameynayaa 1.5% ~ 2.5% iyadoo loo eegayo xaddiga ω (S) inta lagu dhex dhalaalayo foornada .

Isla mar ahaantaana, xirmada daawada spheroidizing waxay qaadataa xirmo daaweyn ah oo ah nooca biyo xireenka. Marka hore, ku dar 1.7% wakiilka dawada fosco NODALLOY7RE ee biyo xidheenka dhinaca baakada hoose ee baakada, isukeen oo isafgarad, isticmaalna 0.2% budada silikoon carbide ah iyo 0.3% yar Xulka 75SiFe wuxuu ku daboolan yahay hal lakab midba midka kale , iyo taabashada ka dib, waxaa lagu daboolayaa bir cadaadis leh, iyo 0.3% Foseke 390 inoculant ayaa lagu daraa dhinaca kale ee dhalada birta dhalaashay. Markaad birta garaaceyso, 55% ~ 60% wadarta mugga birta dhalaashay marka hore waa la dhaqaa. Ka dib marka fal-celinta 'spheroidizing reactions' la dhammeeyo, 1.2% 75SiFe-C inoculant ayaa lagu darayaa oo birta dhalaalaysa ee hadhay ayaa la soo shubayaa, oo caleenta la daadinayaa.

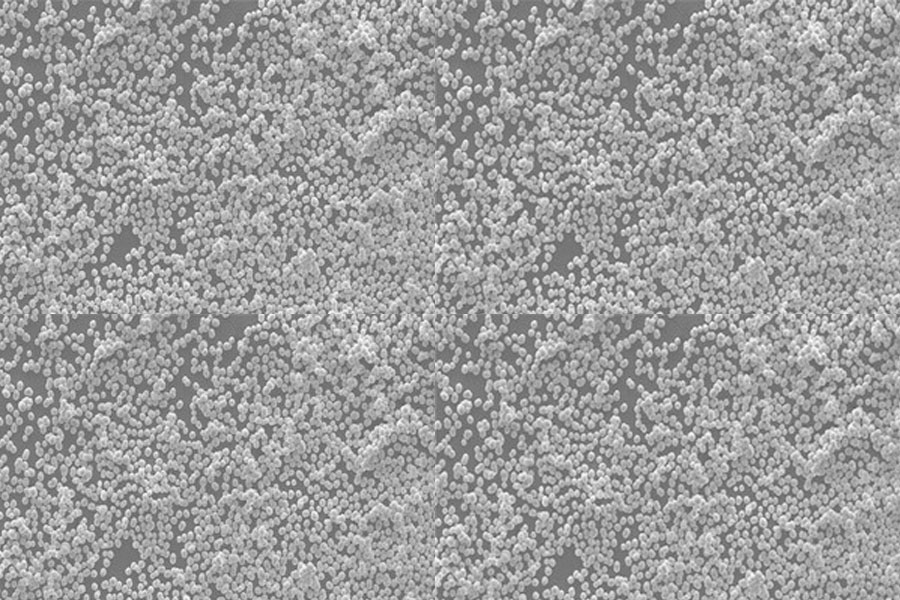

3.2 Natiijooyinka baaritaanka

Waxyaabaha ay ka kooban tahay asalka asalka ah ee birta la shubay ka hor iyo ka dib dabargoynta, astaamaha farsamada iyo qaab dhismeedka biraha ee 25mm hal tuubbo ah oo tijaabo ah, iyo habka qiimeynta ee qiyaasta spheroidization ee qaab dhismeedka biraha waxaa si otomaatig ah u ogaadaa nidaamka falanqaynta sawir-biraha .

4. Falanqaynta natiijada

4.1 Saameynta walxaha ugu muhiimsan ee heerka spheroidization

- C, Si: C wuxuu dhiirrigelin karaa garaafinta oo wuxuu yareyn karaa u janjeerka afka cad, laakiin qadar sare oo ah ω (C) ayaa ka dhigi doonta CE aad u sarreeya oo si fudud u sababi doonta garaafka inuu sabeeyo, guud ahaanna laga xakameeyo 3.7% ~ 3.9%. Si wuxuu xoojin karaa kartida garaafka wuxuuna baabiin karaa sibidhka. Marka Si loogu daro sunta, waxay si weyn u yareyn kartaa awoodda supercooling ee birta dhalaashay. Si loo hagaajiyo saameynta tallaalka, xaddiga ω (Si) ee birta asalka ah ee asalka ah ayaa laga yareeyay 1.3% ilaa 1.5% ilaa 0.8% ilaa 1.2%, iyo xaddiga ω (final-ka Si) waxaa lagu xakumay 2.60% ilaa 3.00%.

- Mn: Inta lagu gudajiro howsha crystallization, Mn waxay kordhisaa u janjeerida macdanta birta in lagu kiciyo waxayna kor uqaadaa sameynta carbides (FeMn) 3C. Nidaamka isbeddelka eutectoid, Mn wuxuu yareeyaa heerkulka isbeddelka eutectoid, wuxuu dejiyaa oo sifeeyaa pearlite. Mn saameyn badan kuma laha heerka spheroidization. Saamaynta alaabta ceeriin awgeed, guud ahaan xakamayso ω (Mn) <0.30%.

- P: Marka ω (P) <0.05%, waa mid lagu milmi karo Fe, wayna adagtahay in la sameeyo fosfooraska eutectic, kaas oo saameyn yar ku leh xaddiga spheroidization ee birta ductile.

- S: S waa cunsur quus ka taagan. S wuxuu ku cunaa Mg iyo RE wakiilka spheroidizing inta lagu gudajiro falcelinta spheroidizing, carqaladeynta garaafyada iyo yareynta heerka spheroidizing. Sulfide slag sidoo kale wuxuu ku laaban doonaa baaruud ka hor inta birta dhalaalaysa aysan sii adkayn, mar labaadna waxay cunaysaa walxaha spheroidizing, waxay dardar galineysaa hoos u dhaca spheroidization, waxayna sii saameyneysaa heerka spheroidizing. Si loo gaaro xaddiga spheroidization-ka sareeya, xaddiga ω (S) ee birta ceyriinka waa in laga dhigaa in ka yar 0.02%.

4.2 Daaweynta quudinta

Ka dib marka lacagta la dhalaaliyo, muunado qaado oo falanqee walxaha kiimikada. Marka xaddiga ω (S) uu ka sarreeyo 0.02%, baabba'a ayaa loo baahan yahay.

Mabda'a sicir-celinta soodhaha ash waa: in qadar cayiman oo soodhad ah lagu shubo laydhka, isticmaal qulqulka birta la shubay si uu u dhaqo oo u kiciyo, dambaska soodhaha ayaa ku jajabiya heerkulka sare, qaaciddada falcelintu waa Na2CO3 = Na2O + CO2 ↑: Na2O-da la soo saaray waa birta ku dhalaashay markale Burburka iyo sameynta Na2S, (Na2O) + [FeS] = (Na2S) + (FeO).

Na2CO3 ayaa kala soocaya oo xaliya CO2, oo sababaya kacdoon gacan ka hadal ah birta dhalaashay, taas oo dhiirrigelinaysa hannaanka baaba'aynta. Soda ash slag waa fududahay in la qulqulo oo si dhakhso ah loo sabeeyo, iyo waqtiga falcelinta desulfurization waa mid aad u gaaban. Ka dib marka la nadiifiyo, slag waa in laga saaraa waqtiga, haddii kale waxay ku laaban doontaa baaruud. 4.3 Daaweynta pre-deoxidation, daaweynta spheroidization iyo daaweynta tallaalka Foseke 390 wakiilka ku daweynta ayaa doorka ka qaata daaweynta pre-deoxidation-ka ee boorsada, isla mar ahaantaana wuxuu kordhiyaa xuddunta garaafka nukleerka iyo tirada garaafyada dhinacyada aag kasta, sidoo kale wuu awoodaa kordhiya heerka nuugista ee Mg. Si muuqata u wanaajiya awoodda looga hor tago hoos u dhaca dhaqaale iyo kordhinta xaddiga spheroidization. Fochke inoculant wuxuu ka kooban yahay ω (Si) = 60% ~ 70%, ω (Ca) = 0.4% ~ 2.0%, ω (Ba) = 7% ~ 11%, kuwaas oo Ba ay dheereyn karto waqtiga fiditaanka. Heerka NODALLOY7RE ee Fozco Nodulizer ayaa la xushay, iyo ω (Si) = 40% ~ 50%, ω (Mg) = 7.0% ~ 8.0%, ω (RE) = 0.3% ~ 1.0%, ω (Ca) = 1.5 % ~ 2.5%, ω (Al) <1.0%. Maaddaama birta la dhalaalay ay marayso baabinta iyo daaweynta kahoreynta jirka, cunsurrada ku cuna qanjiraha birta dhalaalay aad ayaa loo yareeyay, sidaa darteed nodulizer oo leh qadar yar oo ah ω (RE) ayaa loo xushay si loo yareeyo xumaanta qaab-dhismeedka qaab-dhismeedka garaafka ee 'spheroidal graphite morphology' ; Qeybta ugu weyn ee ficilku waa Mg; Ca iyo Al ayaa door ka ciyaari kara xoojinta qalliinka. Iyadoo la adeegsanayo carbide silicon iyo ferrosilicon oo la isku daro daaweynta tallaalka, barta dhalaalaysa ee silikoon carbide waxay ku saabsan tahay 1600 ° C, iyo garaafka 'nucleus crystal nucleus' waa la kordhiyay inta lagu jiro xoojinta, iyo qiyaaso badan oo loo yaqaan 'ferrosilicon' ayaa loo isticmaalaa tallaalka, taas oo ka hortagi karta qanjirka 'spheroidization' inuu hoos u dhaco.

5 Gunaanad

Soo saarida birta birta ah ee loo yaqaan 'nodular iron cast,' marka qiyaasta spheroidization looga baahan yahay inay gaarto in ka badan 90%, tallaabooyinka soo socda ayaa la qaadan karaa:

- (1) Xullo lacag tayo sare leh si loo yareeyo cunsuriyada ku jirta de-spheroidization.

- (2) Xullo wakiil daawada spheroidizing-ka ah oo leh qaddar yar oo ah ω (RE) si loo yareeyo saamaynta sii xumaanaysa ee RE ee qaab-dhismeedka garaafka spheroidal graphite.

- (3) Mawduuca ω (S) ee asalka asalka ah ee birta la shubay waa inuu ka yaraadaa 0.020%, taas oo yareyn karta isticmaalka nodulizer, gaar ahaan walxaha nodulized-ka ah ee ay ku baaba'day baaruudda labaad ee salfidka.

- (4) Pre-deoxidize birta la shubay, kordhinta tirada jaantusyada garaafyada halkii cutub, kordhinta qiyaasta spheroidization, si weyn u wanaajinaysa awooda iska caabinta hoos u dhaca dhaqaalaha, iyo kordhinta waqtiga fiditaanka wax ku oolka ah.

- (5) Iska yaree qadarka ω (Si) birta asalka ah ee asalka ah, kordhinta xaddiga wakiilka spheroidizing, sunta iyo wakiilashada kaladuwan ee kaladuwan, iyo in la xoojiyo daaweynta tallaalka.

Fadlan hayso isha iyo cinwaanka maqaalkan si dib loogu daabaco: Sida loo hagaajiyo cabbiraadaha hannaanka loo shubay ee qiyaasta spheroidization-ka

Minghe Shirkadda Die Casting waxaa ka go'an in ay soosaaraan oo ay bixiyaan Qaybo ka ridaya tayo iyo waxqabad sare (biraha qaybo ka ridaya dhiman kala duwan inta badan ka mid yihiin Khafiifa-Wall dhinta ridaya,Hot ridaya die Cast,Kursiga Qabow Die Casting), Adeeg Wareeg ah (Adeegga Tartanka Dhimashada,Qalabka Mashiinka,Samaynta Furka, Daaweynta Dusha sare) .Caadi kasta oo Aluminium ah shubitaan, magnesium ama Zamak / zinc shubida iyo shuruudaha kale ee shubanka ayaa lagu soo dhaweynayaa inaad nala soo xiriirto.

Iyada oo ay gacanta ku hayaan ISO9001 iyo TS 16949, dhammaan geeddi-socodyada waxaa lagu fuliyaa iyada oo loo marayo boqollaal mashiinno shub ah oo dhimanaya, mashiinnada 5-dhidibka, iyo tas-hiilaadka kale, oo ka bilaabma qarxiyayaal ilaa mashiinnada dharka lagu nadiifiyo ee Ultra Sonic.Minghe ma ahan oo keliya qalab casri ah laakiin sidoo kale waxay leedahay xirfadle koox injineero khibrad leh, wadayaal iyo kormeerayaal si niyada macaamiisha ay u noqoto mid run ah.

Soo saaraha qandaraasle ee shubka dhinta. Awoodda waxaa ka mid ah qaybaha qabow ee aluminium ee qaybaha shubista laga bilaabo 0.15 lbs. illaa 6 rodol, isbeddel deg deg ah oo la dejiyay, iyo qalabaynta. Adeegyada qiimaha lagu daro waxaa ka mid ah sifaynta, gariirka, qashin-qubka, xabbadda toogashada, ranjiyeynta, dahaadhka, dahaadhka, isku-ururinta, iyo qalabaynta. Qalabka lala shaqeeyay waxaa ka mid ah alloysyada sida 360, 380, 383, iyo 413.

Zinc wuxuu u dhintaa caawinta naqshadeynta / adeegyada injineernimada isku mar. Soo saaraha gaarka ah ee saxda saxda ah ee looxyada. Daarayaasha yar-yar, cast-yada u dhinta cadaadiska sare, jilayaasha caaryada badan-slide, shubka caaryada caadiga ah, cutubka dhinta iyo kuwa madaxa-bannaan ee loo dhinto iyo daloolka dahaarka saanlan ayaa la soo saari karaa. Jilayaasha waxaa lagu soo saari karaa dherer iyo ballac ilaa 24 gudaha. +/- 0.0005 gudaha. Dulqaad.

ISO 9001: soo saaraha shahaadada leh ee loo yaqaan 'cast cast magnesium', Awoodaha waxaa ka mid ah dhimista cadaadiska sare ee magnesium oo loo ridayo ilaa 2015 ton qol kulul & 200 ton oo qol qabow ah, naqshadeynta qalabka, nadiifinta, wax u sameynta, mashiinada, budada & dareeraha rinjiyeynta, QA buuxda oo leh awooda CMM , ururinta, baakadaha & gaarsiinta.

ITAF16949 la xaqiijiyay. Adeeg Dheeraad Dheeraad ah Ayaa Kujira maalgelinta maalgelinta,ciida ciid,Dabaaldeg Shaqo, Casting Foam Fost,Khadka Centrifugal,Dabka Vacuum Casting,Qaab Joogtada ah, Awoodda waxaa ka mid ah EDI, kaalmada injineernimada, qaabeynta adag iyo ka shaqeynta heerka labaad.

Warshadaha Kabka Qaybaha Daraasada Kiiska ee loogu talagalay: Gawaarida, Baaskiiladaha, Diyaaradaha, Qalabka muusikada, Biyaha, Qalabka indhaha, Dareemayaasha, Moodooyinka, Aaladaha elektarooniga ah, Xiritaanka, Saacadaha, Mashiinnada, Mashiinnada, Qalabka guryaha, Dahabka, Jigs, Telecom, Laydhka, Qalabka Caafimaadka, Qalabka Sawirka, Robotyo, farshaxanno, qalabka codka, Qalabka isboortiga, Qalabaynta, Caruurta iyo waxyaabo kale oo badan.

Maxaan kaa caawin karnaa inaad sameyso marka xigta?

Tag bogga hore ee loogu talagalay Shiinaha dhinta Casting

→Qeybaha kabkaOgow waxaan soo qabanay.

Tips Tilmaamaha Halaasiga ah ee Ku Saabsan Adeegyada Cast Cast

By Soo saaraha Minghe Die Casting | Qeybaha: Maqaallo waxtar leh |Waxyaabaha Tags: Casting Aluminium, Tuurista Zinc, Ridaya Magnesium, Qalitaanka Titanium, Qalabka birta ee birta, Naxaas naxaas ah,Raxaama Naxaas,Video Tuuraya,Taariikhda Shirkadda,Calaamadda Aluminum Die Casting | Faallooyinka Off