Drilling

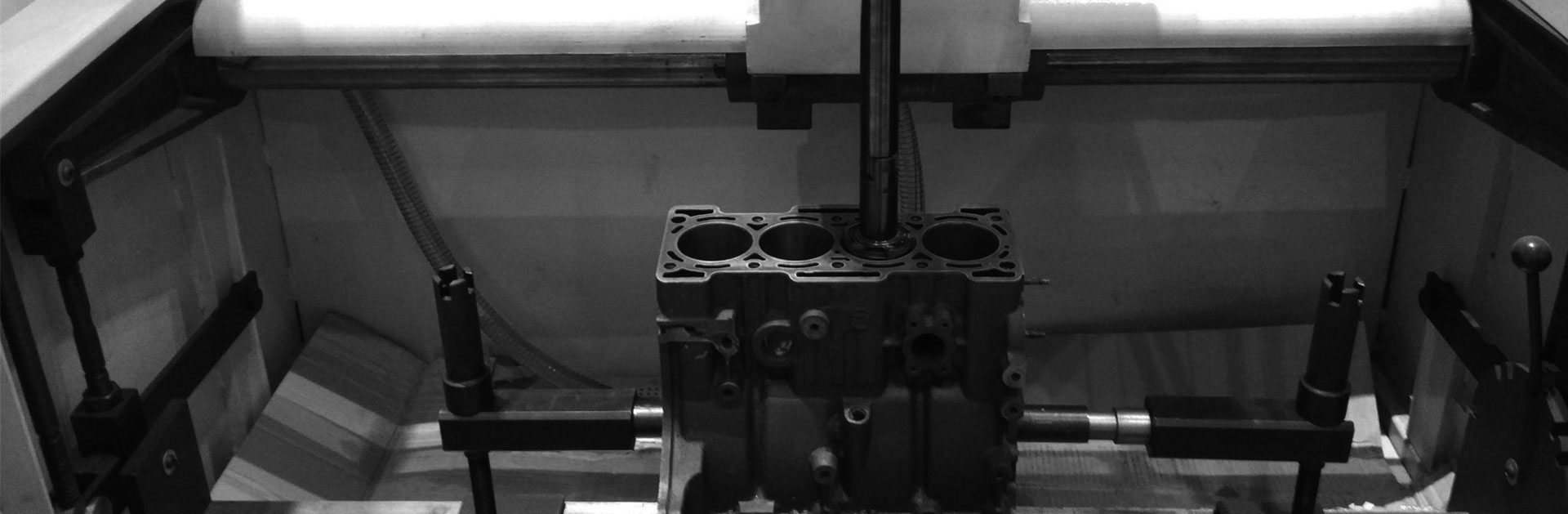

Waa maxay Habka Qodista Cnc & Mashiinka Qodista & - Adeegyada Qodista

Nooc kasta oo mishiin ah lama samayn karo god la'aan. Si aad isugu xirto qaybaha, godad kala geddisan oo kala duwan, godad pin ama godad rivet ah oo cabbirro kala duwan leh ayaa loo baahan yahay; si loo hagaajiyo qaybaha gudbinta, godad kala duwan oo dhejis ah ayaa loo baahan yahay; Qaybaha mashiinka laftoodu sidoo kale waxay leeyihiin godad badan oo kala duwan (sida godadka saliidda, Habka waxqabadka, godka miisaanka oo yaraada, iwm.). Qalliinka daloolinta daloolka si godku u buuxiyo shuruudaha waxaa loo yaqaannaa daloolinta daloolka.

Dusha sare ee daloolka gudaha waa mid ka mid ah dusha sare ee muhiimka ah ee ka kooban qaybaha farsamada. Qeybaha farsamada, qeybaha godadka leh guud ahaan waxay gaarayaan 50% ilaa 80% wadarta tirada qaybaha. Noocyada godadku sidoo kale way kala duwan yihiin, oo ay ku jiraan godad dhululubo ah, godad macmal ah, godad dun leh, iyo godad qaabeeya.

Godadka caadiga ah ee cylindrical-ka way ka duwan yihiin godadka guud iyo godadka dhaadheer, godadka dhaadheerna way adag tahay in mashiin la sameeyo.

Adeegyada qodista Minghe ayaa markii hore lagu daray si loo amaano loona taageero awoodayada sameynta. Maanta, macaamiisha waxay adeegsadaan adeegyadeena hormarinta howlaha qodista xitaa marka sameynta aan loo baahneyn. Muddo 35 sano ah, waxaan horumarinay adeegyadeena qodista si aan macaamiisha u siino xalka saxda ah ee codsigooda gaarka ah. Injineerada Minghe ayaa dib u eegi doona qeexida alaabta, qalabka ka bixitaanka qalabka iyo shuruudaha mugga si loo xusho xalka ugu kharashka badan ee mashruuca qodistaada.

Shuruudaha Farsamada ee Daloolinta Hole

In geeddi-socodka waxqabadka godka, waxaa lagama maarmaan ah in laga fogaado dhibaatooyinka sida ballaarinta ballaca dhexroor baaxad weyn, dusha sare ee dusha sare ee shaqada, iyo xirashada xad-dhaafka ah ee qodista, si looga hortago inay saameyn ku yeelato tayada qodista iyo kordhinta howsha. kharashka. Shuruudaha farsamo ee soo socda waa in la hubiyaa inta suurtogalka ah:

- - Saxnaanta cabbirka: saxnaanta dhexroorka iyo qoto dheer ee godka;

- - Saxsanaanta Qaabka: Wareegga godka, silsiladda iyo toosnaanta dhidibka;

- - Saxnaanta booska: wadajirka u dhexeeya godka iyo dhidibka godka ama dhidibka wareegga dibadda; isbarbaryaaca iyo isdhaafsiga godka iyo godka ama godka iyo meelaha kale, iwm.

Isla mar ahaantaana, waxyaabaha soo socda ee 5 waa in sidoo kale la tixgeliyaa:

- - Qaab dhismeedka qotoda dheer ee godka iyo dulqaad dusha dulqaadka dulqaadashada;

- - Astaamaha qaabdhismeedka shaqada, oo ay ku jiraan xasilloonida dib-u-habeynta iyo wareejinta;

- - Xawaaraha awoodda, nidaamka qaboojiyaha iyo xasilloonida qalabka mashiinka;

- - Dufcaddii howsha;

- - Qiimaha hawlgalka;

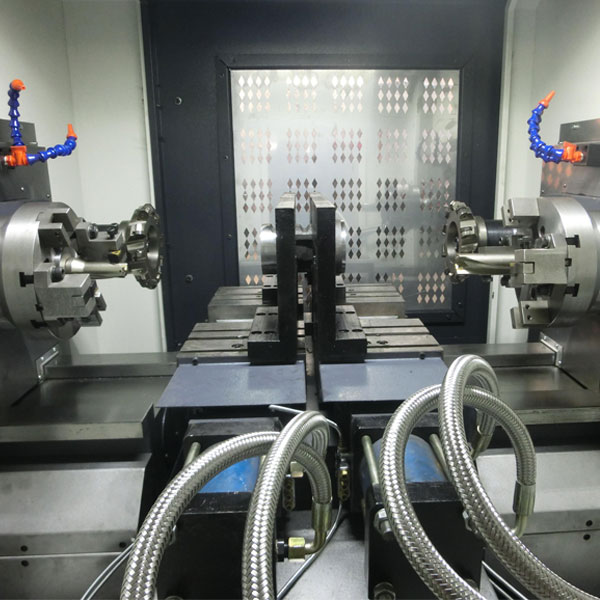

Noocyada kala duwan ee Mashiinka Qodista - Adeegyada Qodista Cnc-ga ee laga heli karo Minghe

Godadka kala duwan ee qaybaha caaryada, sida daloollada godadka, godadka godadka, godadka biinanka, godadka manjarka, godadka meertada xudunta u ah, iwm.

Hababka wax soo saar ee badanaa la isticmaalo ayaa lagu muujiyey jadwalka.

| nooca | Content |

| Qodista Qaybta Keli ah | Qeyb keli ah ayaa si toos ah loo qoday iyada oo loo eegayo booska calaamadeynta |

| Duuliye Pilot | God ka dalool hal qayb marka hore, oo tanna hage ahaan ugu isticmaal qoditaanka meelaha kale. Hal qayb ayaa loo isticmaali karaa qodista tooska ah ee jihada ka soo horjeedda markii la qodayo; sidoo kale waxay u horseedi kartaa godka daloolka si looga dhigo qodista jihada ka soo horjeedda. |

| Qodista Iskujira | Si loo hubiyo masaafada daloolka ee qaybaha, labada qaybood ayaa lagu xidhi karaa silsilado is barbar socda ama lagu dhejin karaa boolal si ay u samaystaan mid dhan, godadkuna waa la qodmi karaa isla wakhtigaas sida ku xusan calaamadda. |

Dib-u-hagaajinta Makiinado

Inta badan waxaa jira godad pin ah, godad ejector, godad asaasiga ah, iwm oo ku jira caaryada oo u baahan in la farsameeyo ka dib marka wax la qoro ama inta la kulmayo. Xaqiijinta wax soo saarku guud ahaan waa IT6 illaa IT8, oo qalloocsanaanta kama yaraaneyso Ra3.2μm.

Mabaadi'da Guud Ee Magacaabista

| nooca | Content | |

| Dhexroor Workpiece | Qoday oo dib loo rogay by fitter | |

| 10 ~ 20 | Ku shaqeynaya qodista, dib-u-eegista, dib-u-habeynta, iwm. | |

| > 20 | Horey ayaa loogu xakameynayaa daloolka mashiinka, ka dibna qodista iyo farsamaynta mashiinka caajiska ah | |

| Ma u baahan tahay in la demiyo daloolka | Marka dib loo cusbooneysiiyo, xaddiga shiidiyuhu waa inuu noqdaa 0.02 ~ 0.03. Godadka waa in la ilaaliyaa inta lagu jiro daaweynta kuleylka oo mar labaad ayey dhulka la dhigidoontaa marka la isu geeyo | |

| Isku-darka iskudhafka maadooyinka kala duwan | Markaad dib u cusbooneysiineyso qaybaha maaddooyinka kala duwan, dib-u-habeynta waa in laga sameeyaa maaddooyinka adag | |

| Qalabeynta qalabka dib-u-dhiska | Iyada oo loo marayo dib u habeynta godka qalabka adag, marka hore hubi in daloolku qalloocan yahay, in lagu cusbooneysiiyo reamer carbide caadi ah, ama dib loogu cusbooneysiiyo duub duug ah, ka dibna isticmaal bir birqaya oo wax shiidaya si aad ugu xoqdo cabirka loo baahan yahay | |

| Reamed god | Marka daloolka aan dib loo rogin, qoto dheer ee godka dib-u-soo-celinta waa in la qoto-dheeraadaa, iyadoo laga tegayo dhererka qaybta jarista ee reamer-ka si loo hubiyo dhexroorka waxtarka leh ee godka; sidoo kale waxaa dib loogu cusbooneysiin karaa reamer caadi ah, ka dibna dib loogu cusbooneysiinayaa godka reamer duug ah oo dhulka dhigay qeybta goynta. Hoos aan laxirin | |

| Qalabka mashiinka | Ka dib marka shaqada la isku xiro hal mar, qodista, ka-fiirsashada, iyo dib-u-habaynta ayaa si joogto ah loo sameeyaa si loo hubiyo isku-dheellitirka iyo isbarbar dhigga godka | |

Mashiinka Godka Qoto dheer

Godadka kanaalka qaboojinta, godadka kululeeyaha iyo qeyb ka mid ah godadka biinanka ciin ee caaga caagga ah waxay u baahan yihiin in si qoto dheer looga shaqeeyo. Guud ahaan, saxnaanta godka biyaha qaboojinta ma badna, laakiin waa lagama maarmaan in laga hortago leexashada; si loo hubiyo hufnaanta wareejinta kuleylka, godka kuleyliyaha wuxuu leeyahay shuruudo gaar ah oo ku saabsan dhexroorka daloolka iyo qallafsanaanta, dhexroorka godka ayaa 0.1 ~ 0.3mm ka weyn usha kuleylka, qallafsanaantuna waa Ra12.5 ~ 6.3 μm; halka daloolka ejector uu ubaahan yahay heer sare, saxsanaanta guud waa IT8 waxaana jira shuruudo toosan iyo qallafsanaan.

Ka shaqeynta daloolka

Godad badan oo ku jira caaryada ayaa loo baahan yahay si loo hubiyo fogaanta daloolka, fogaanta cirifka godka, isbarbar dhigga dhidibka god kasta, u dhignaanta wejiga dhamaadka, iyo wada noolaanshaha godadka ka dib marka labada qaybood la isu geeyo. Nidaamka godka noocan ah guud ahaan waa la shaqeeyaa marka hore, ka dibna godadka waxaa lagu farsameeyaa iyadoo la xoqayo.

Xulo Habka Qoditaanka Ugu Fiican

Kadib markaad baartid liistada adeegyada Daaweynta Dusha sare, xulo hanaan ku saleysan tixgelinta muhiimka ah, sida waqtiga wax soo saarka, qiimaha-waxtarka, dulqaadka qayb, adkaysiga iyo codsiyada. Mashiinka CNC ee dulqaadka sarreeya, qaybaha leexashada laguma talinayo in lagu dabaqo dhammaystirka dusha sare ee birta, maxaa yeelay daaweyntu waxay beddeli kartaa cabbirka qaybta dhammaatay iyada oo la saarayo ama lagu daro qaddar yar oo qalab ah.

Nala soo xiriir ama Email sales@hmminghe.com si aad u aragto sida dadkeenna, qalabkeenna iyo qalabkeennu u keeni karaan tayada ugu wanaagsan ee ugu qiimaha badan mashruuca qodistaada.