Sidee Loo Helaa Booska Ugu Fiican Vacuum Valve In The Die Casting Tooling?

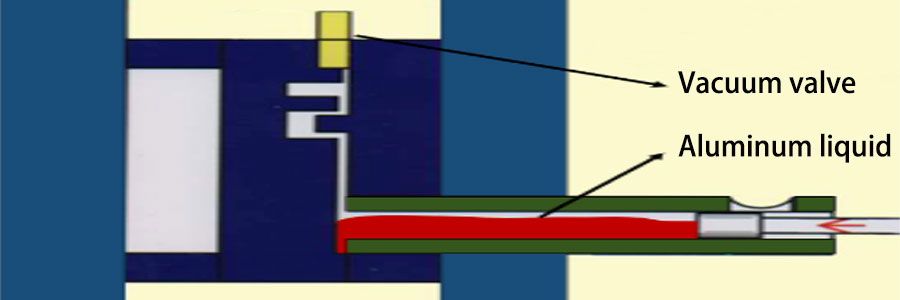

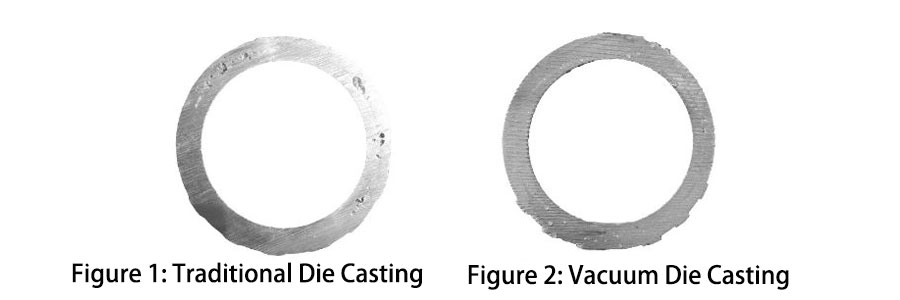

Marka la barbardhigo caaryada ciidda iyo tuurista cuf isjiidadka, microstructure-ka tuurista dhaqameedku kuma qanacsana. Sababta ugu weyn ayaa ah in cirbadeynta qulqulka biraha xawaaraha sare ee irridda ay fududahay in lala xiriiro daloolka marka loo eego marka birta si tartiib ah loogu shubo ciidda ama hawo wasakheysan. Ujeedada habka faakiyuumku u dhinto ayaa ah in la yareeyo xidhiidhkan gaaska-dareeraha ah. Sidaa darteed, si hufan u daalidda gaaska ku jira godka ayaa fure u ah naqshadeynta caaryada faakiyuumka dhinta.

Wixii wasakhahaasi u dhinta, ma jiro farqi muhiim u dhexeeya naqshadeynta qiiqa dhaqameed iyo naqshadeynta qiiqa faakiyuukha. Dariiqa kaliya ee lagu dhammayn karo waa kan hore oo ah qiiqa aan caadiga ahayn, kaas oo u adeegsada socodka biraha gaaska qiiqa, taas oo ah waxa loogu yeero cirbad cadaadis togan; kan dambe ayaa ah Mid Qiiqa, taas oo ah, adoo adeegsanaya qalab faaruq ah si aad uga soo saarto gaaska godka ku jira, waxaa sidoo kale loo yaqaannaa duritaanka cadaadiska xun. Marka laga hadlayo saameynta qiiqa, farqi weyn ayaa u dhexeeya labadooda. Codsiga qiiqa faakiyuumka saxda ahi wuxuu si weyn u yareyn doonaa gaaska ku jira godka, halkaas oo si wax ku ool ah loogu hagaajinayo tayada wax soo saarka.

Maqaalkani wuxuu isku daraa Shaybaarka Shiinaha ee loo yaqaan 'Cloud Die Casting Cloud Computing Platform' si looga wada hadlo meesha uu ku yaallo qalabka faakiyuumka ee ku lug leh naqshadeynta nidaamka caaryada faakuumka ah, iyadoo diiradda la saarayo bal in qalabka faakiyuumku ka sii fogaado iridda hoose ama u dhow?

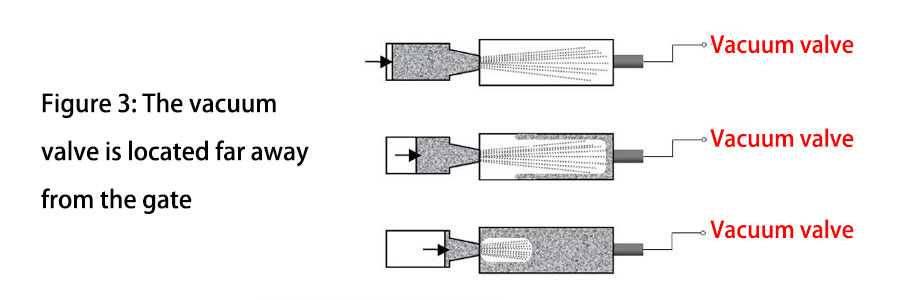

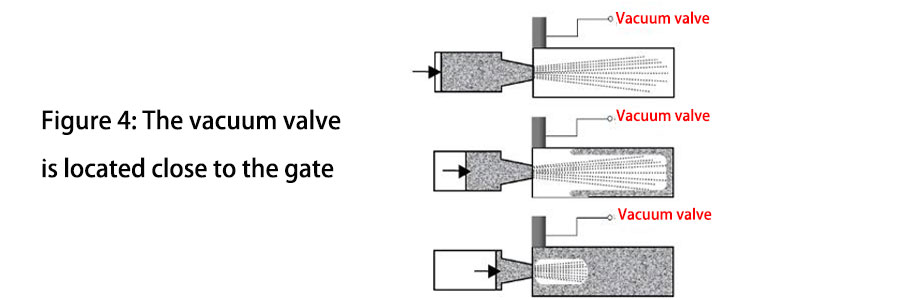

In geeddi-socodka faakiyuumka naqshadeynta dhinta-tuurista, booska faakiyuumku waa inuu awood u yeeshaa inuu furfuro faakiyuumka oo furan muddo dheer, si loo soo saaro gaaska ugu badan ee suurtogalka ah.

Bamka faakiyuumka waa in lagu dhejiyaa halka ay ku dareyso daawaha ugu dambeeya, laakiin booskani wuxuu noqon karaa mid isdifaacaya, sida ku cad Jaantuska 3: Sida shubka caadiga loo dhinto, faakiyuumku wuxuu u keenaa qulqulka atomiga. Haddii waalka faakiyuunka lagu dhejiyo meesha ugu fog albaabka Meel, waalka faakiyuumka ayaa laga yaabaa in la xidho goor hore hawsha buuxinta saabka.

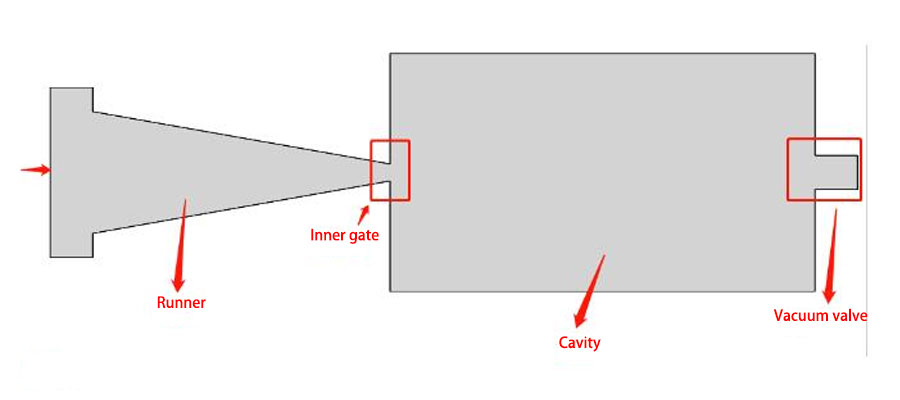

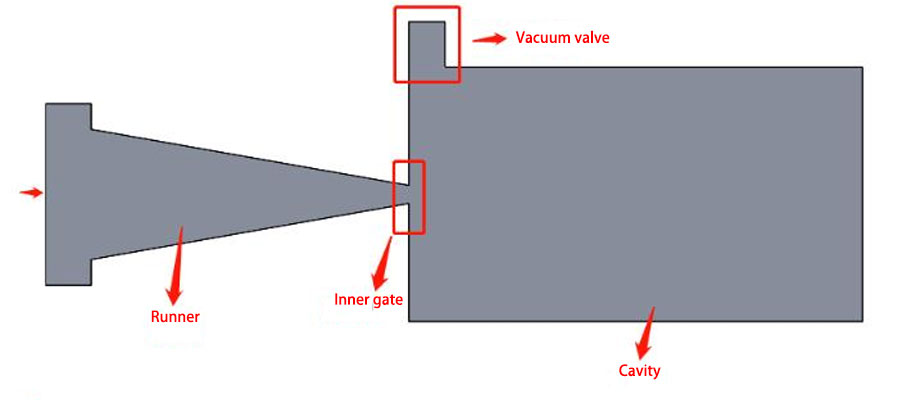

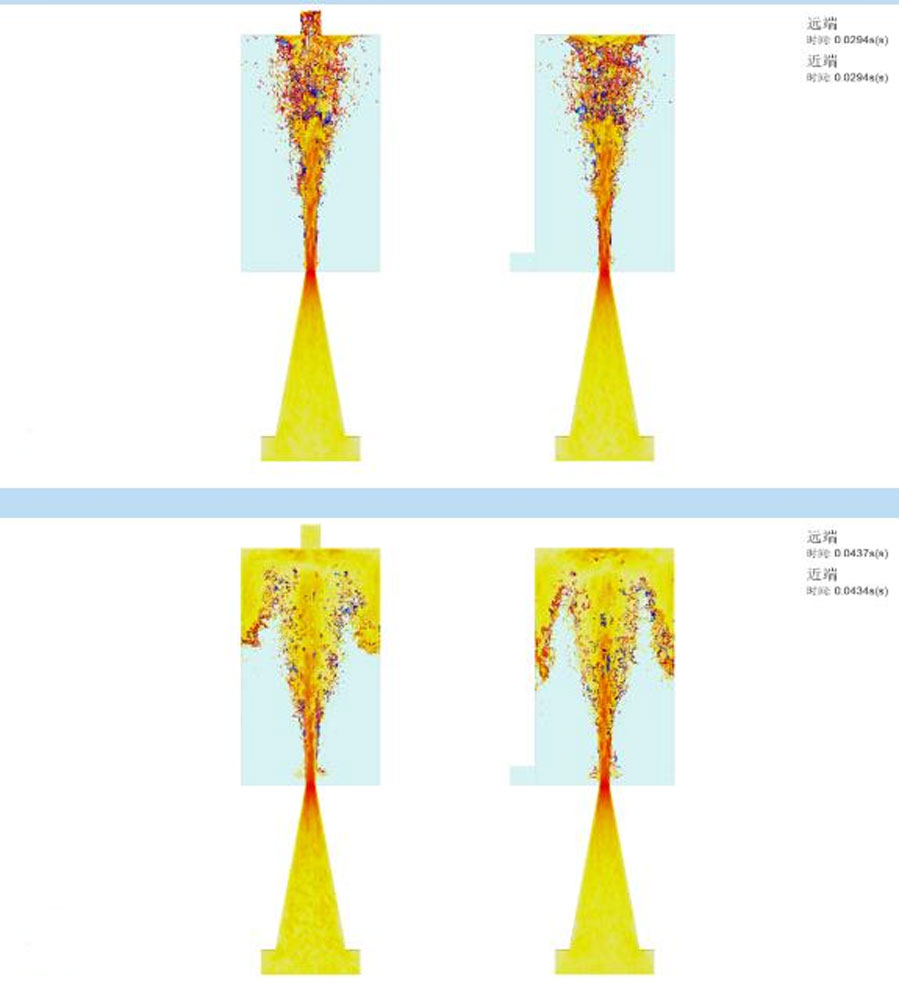

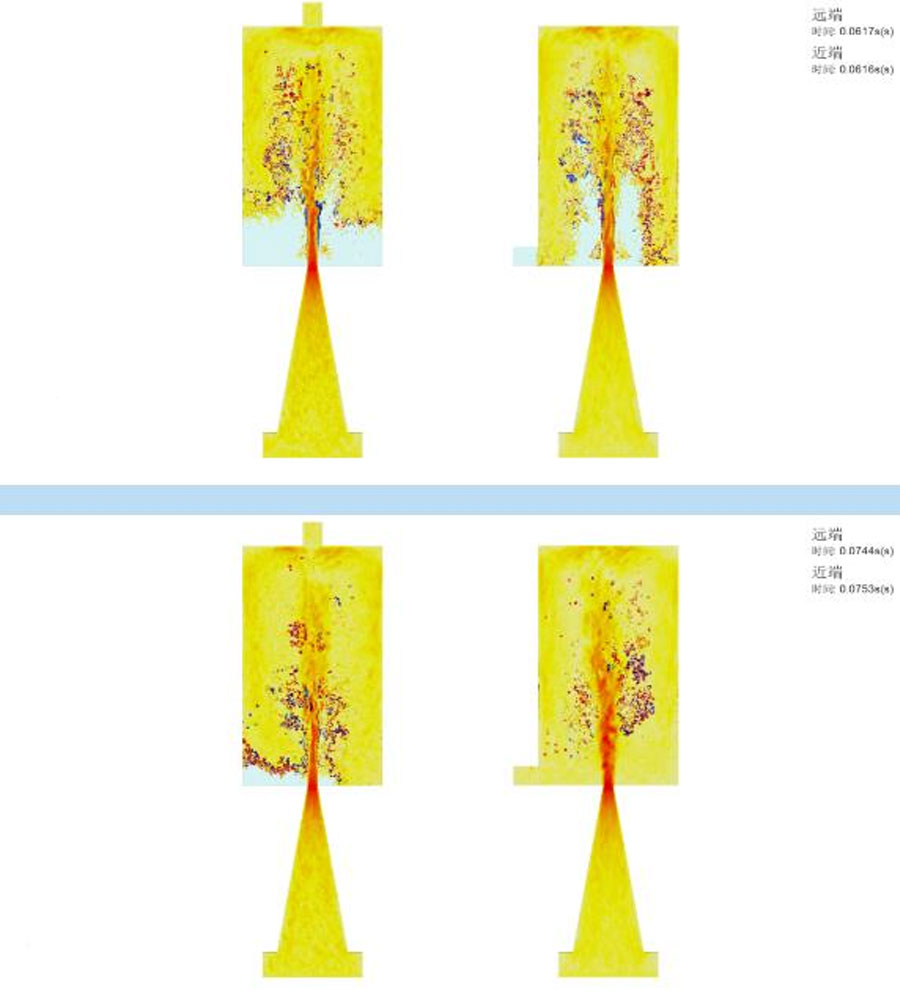

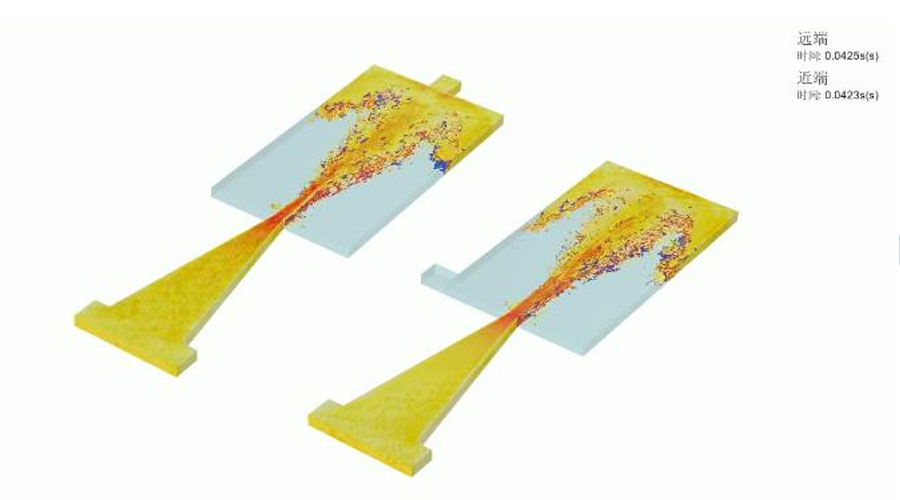

Si si cad loogu muujiyo aragtida kor ku xusan, laba moodel oo bartilmaameed ah ayaa halkan loo qaabeeyey, sida ku cad sawirrada 5 iyo 6 ee hoose. Jilidda jilitaanka buuxinta caaryada Die-casting waxaa lagu fuliyaa iyada oo loo marayo mashiinka xisaabinta daruuriga dhinta ee Shiinaha si loo fiirsado qulqulka daloolka dhalaalaya ee daloolka isla markaana si macquul ah u fahmo Farqiga u dhexeeya labada boos ee waalka faakuumka ee geedi socodka dhabta ah ee dhimashada.

Isbarbar dhigga Natiijooyinka Isleelinta Cloud Cloud

Tusaalaha bidixda, marka waalka waalka uu ku yaal meel aad uga fog iridda, waalka feylalka ayaa xanniban bilowga buuxinta;

Tusaalaha midigta, marka qalabka faakiyuumku ku yaallo meel u dhow iridda, qalabka faakiyuumku wuxuu sii wadi doonaa inuu shaqeeyo inta lagu jiro hawsha buuxinta

Waa la arki karaa in nashqadeynta faakiyuumka faakuumka ku jira Jaantuska 5 uu runtii yahay mid caqli-gal ah. Marka birta la shubay la buuxiyo, waalka waalka ayaa horay loo xiray, iyo waalka faakuumka ee Jaantuska 6 ayaa ilaalin kara socodka ugu badan ee aan xannibaadda lahayn, kaas oo qiimo u leh qiiqa faakiyuumka. Waqti (qiyaastii 40ms tusaalahan). Dabcan, tusaalahan tusaalahan waa mid fudud. Naqshadaynta dhabta ah iyo shaqada horumarka, qaabeynta qaabka waalka waayuhu wuxuu adeegsan karaa awooda jilitaanka dhinta-rida ee awoodda badan ee mashiinka xisaabinta daruuriga Shiinaha ee Dhimashada si loo go'aamiyo booska ugu fiican.

Fadlan hayso isha iyo cinwaanka maqaalkan si dib loogu daabaco:Sidee Loo Helaa Booska Ugu Fiican Vacuum Valve In The Die Casting Tooling?

Minghe Shirkadda Die Casting waxaa ka go'an in ay soosaaraan oo ay bixiyaan Qaybo ka ridaya tayo iyo waxqabad sare (biraha qaybo ka ridaya dhiman kala duwan inta badan ka mid yihiin Khafiifa-Wall dhinta ridaya,Hot ridaya die Cast,Kursiga Qabow Die Casting), Adeeg Wareeg ah (Adeegga Tartanka Dhimashada,Qalabka Mashiinka,Samaynta Furka, Daaweynta Dusha sare) .Caadi kasta oo Aluminium ah shubitaan, magnesium ama Zamak / zinc shubida iyo shuruudaha kale ee shubanka ayaa lagu soo dhaweynayaa inaad nala soo xiriirto.

Iyada oo ay gacanta ku hayaan ISO9001 iyo TS 16949, dhammaan geeddi-socodyada waxaa lagu fuliyaa iyada oo loo marayo boqollaal mashiinno shub ah oo dhimanaya, mashiinnada 5-dhidibka, iyo tas-hiilaadka kale, oo ka bilaabma qarxiyayaal ilaa mashiinnada dharka lagu nadiifiyo ee Ultra Sonic.Minghe ma ahan oo keliya qalab casri ah laakiin sidoo kale waxay leedahay xirfadle koox injineero khibrad leh, wadayaal iyo kormeerayaal si niyada macaamiisha ay u noqoto mid run ah.

Soo saaraha qandaraasle ee shubka dhinta. Awoodda waxaa ka mid ah qaybaha qabow ee aluminium ee qaybaha shubista laga bilaabo 0.15 lbs. illaa 6 rodol, isbeddel deg deg ah oo la dejiyay, iyo qalabaynta. Adeegyada qiimaha lagu daro waxaa ka mid ah sifaynta, gariirka, qashin-qubka, xabbadda toogashada, ranjiyeynta, dahaadhka, dahaadhka, isku-ururinta, iyo qalabaynta. Qalabka lala shaqeeyay waxaa ka mid ah alloysyada sida 360, 380, 383, iyo 413.

Zinc wuxuu u dhintaa caawinta naqshadeynta / adeegyada injineernimada isku mar. Soo saaraha gaarka ah ee saxda saxda ah ee looxyada. Daarayaasha yar-yar, cast-yada u dhinta cadaadiska sare, jilayaasha caaryada badan-slide, shubka caaryada caadiga ah, cutubka dhinta iyo kuwa madaxa-bannaan ee loo dhinto iyo daloolka dahaarka saanlan ayaa la soo saari karaa. Jilayaasha waxaa lagu soo saari karaa dherer iyo ballac ilaa 24 gudaha. +/- 0.0005 gudaha. Dulqaad.

ISO 9001: soo saaraha shahaadada leh ee loo yaqaan 'cast cast magnesium', Awoodaha waxaa ka mid ah dhimista cadaadiska sare ee magnesium oo loo ridayo ilaa 2015 ton qol kulul & 200 ton oo qol qabow ah, naqshadeynta qalabka, nadiifinta, wax u sameynta, mashiinada, budada & dareeraha rinjiyeynta, QA buuxda oo leh awooda CMM , ururinta, baakadaha & gaarsiinta.

ITAF16949 la xaqiijiyay. Adeeg Dheeraad Dheeraad ah Ayaa Kujira maalgelinta maalgelinta,ciida ciid,Dabaaldeg Shaqo, Casting Foam Fost,Khadka Centrifugal,Dabka Vacuum Casting,Qaab Joogtada ah, Awoodda waxaa ka mid ah EDI, kaalmada injineernimada, qaabeynta adag iyo ka shaqeynta heerka labaad.

Warshadaha Kabka Qaybaha Daraasada Kiiska ee loogu talagalay: Gawaarida, Baaskiiladaha, Diyaaradaha, Qalabka muusikada, Biyaha, Qalabka indhaha, Dareemayaasha, Moodooyinka, Aaladaha elektarooniga ah, Xiritaanka, Saacadaha, Mashiinnada, Mashiinnada, Qalabka guryaha, Dahabka, Jigs, Telecom, Laydhka, Qalabka Caafimaadka, Qalabka Sawirka, Robotyo, farshaxanno, qalabka codka, Qalabka isboortiga, Qalabaynta, Caruurta iyo waxyaabo kale oo badan.

Maxaan kaa caawin karnaa inaad sameyso marka xigta?

Tag bogga hore ee loogu talagalay Shiinaha dhinta Casting

→Qeybaha kabkaOgow waxaan soo qabanay.

Tips Tilmaamaha Halaasiga ah ee Ku Saabsan Adeegyada Cast Cast

By Soo saaraha Minghe Die Casting | Qeybaha: Maqaallo waxtar leh |Waxyaabaha Tags: Casting Aluminium, Tuurista Zinc, Ridaya Magnesium, Qalitaanka Titanium, Qalabka birta ee birta, Naxaas naxaas ah,Raxaama Naxaas,Video Tuuraya,Taariikhda Shirkadda,Calaamadda Aluminum Die Casting | Faallooyinka Off